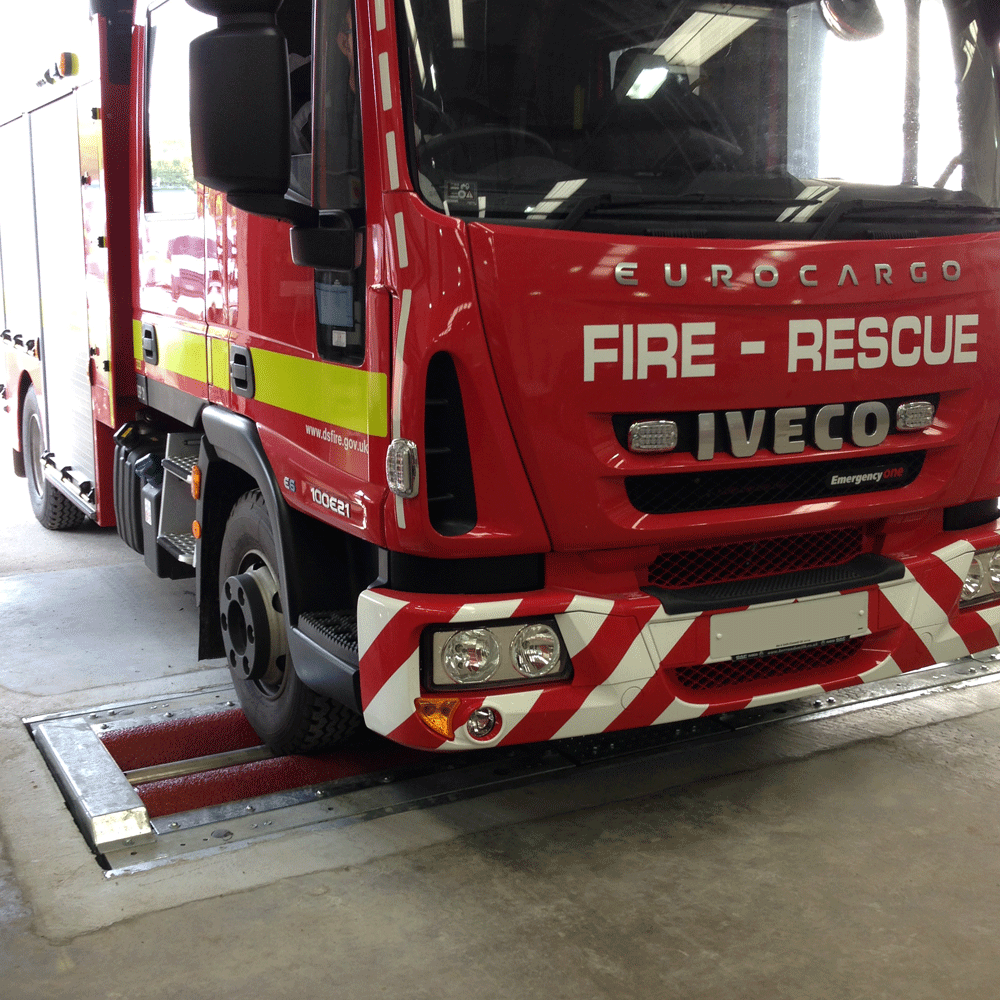

The Sherpa BPS TWIN commercial vehicle roller brake tester is a one man operated machine with tablet operation as standard. A solid state PC which works in conjunction with the 10 “tablet is used for operation of the machine’s easy-to use DVSA software programme (which is updated free at time of calibration). This step-by-step software guides the user through the test sequence and produces a pass/fail test result which can be stored or printed on the supplied a4 printer.

Built in Germany using high quality components, this machine is supplied as standard with a 3 year parts & labour warranty!*

- Bi-directional and 4×4 testing as standard

- Unique, planet-gear drive gearboxes

- 11kw motors

- 18 tonne test weight

- Tablet operation as standard

- Free software updates when calibrated

- National coverage for aftersales support

- ATF Approved and Class IV, VL and VII ATL

*subject to annual calibration contract – excludes rollers which are a wearing part.

| BPS Twin | Specifications |

|---|---|

| Size of each roller bed (L x W x H) | 1415mm x 1145mm x 545mm |

| Diameter of rollers | 265mm |

| Standard length of rollers | 1150mm |

| Maximum axle test weight | 18000kg |

| Gear motor size | 11kw x 2 |

| Test speed | 1.6km/h |

| Maximum brake force measurement | 4200kgf |

| Power requirement | 3 phase (L + N + E) 63amp isolator |

| Tablet operated | Yes 10″ tablet supplied |

| Warranty | 3 years parts & labour* |

This brake tester comes with a 3 year parts and labour warranty which is subject to proof of maintenance.

Warranty exclusions :

Accidental damage, vandalism (non-fair wear and tear), acts of nature and unauthorised repairs by non-Gemco service agents. Package prices are for U.K. Mainland only.

Rollers, printer paper and printer ink.

Proof of maintenance will be required in the event of a warranty claim.

We offer a wide range of service contracts for this brake tester, please contact 0844 249 8101 for more information.

•Additional revenue stream from the same lane

•Carries out tachograph calibration at

•Custom designed wireless electronic console

•Option to mount console on wall or underneath the RBT

•Uses a laser detector to verify the driven wheel rotation

•Laser fitted in thick steel casing to protect from damage

•Gives a high level of accuracy and repeatability

•Quick Tachograph calibration; typically takes

•Optimo is the latest generation Workshop tool from Stoneridge

•Electronics. Available in 17 languages Optimo has been designed to increase efficiency and take tachograph programming into the future.

•This easy to use tool incorporates wireless functionality, tachograph programming & calibration, product application data, the ability to configure an SE5000 or 1381 and more.

•Focusing on speed and ease of use Optimo provides wireless calibration of all radio style tachographs and allows users the option to switch the 2nd source of motion function on/off in SE5000 tachographs and VDO variants.

SHERPA BPS Mobile Commercial Brake Tester ATF Approved

SHERPA BPS Mobile Commercial Brake Tester ATF Approved  SHERPA KOMPAKT 15 Class 4, 5L, 7 & ATF Commercial Brake Tester

SHERPA KOMPAKT 15 Class 4, 5L, 7 & ATF Commercial Brake Tester